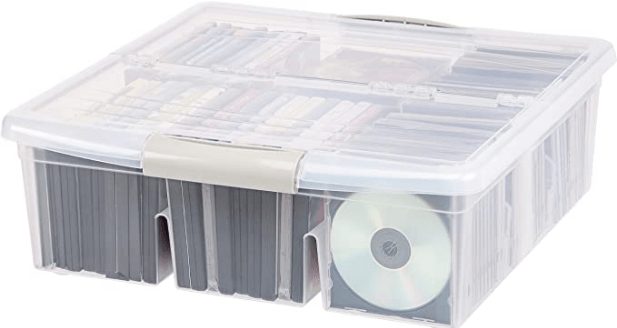

A Storage and Packaging Manufacturer whose division was focused on storage solutions for technology media needed a way to turn their in-house deliverable into a high quality outsourced solution. Plastic Resources, Inc. was selected for the project – and we delivered results.

CHALLENGE

The Manufacturer came to Plastic Resources with a program where they were doing in-house injection molding of their parts. This represented a small part of their total operations, and they decided it would make more sense to outsource the production. The challenge was finding a source to meet custom requirements with a quality deliverable.

SOLUTION

Working closely with Moore Industries (the injection molder in our portfolio) we proposed a unique solution. In addition to taking over the molding, Moore purchased their machines, and also took over the secondary operations.

After we started molding – we found further advantages for the customer in materials areas. The parts were originally molded with clarified PP with propylene elastomer added as an impact modifier. By changing grades to a clarified PP with integral modifiers we were able to improve the impact properties while holding costs in the face of increasing material pricing. Our knowledge and customer focus – paid dividends.

Plastic Resources, Inc. has the knowledge and experience to address all of your plastics molding, extrusion and material selection challenges.

Need solutions from an expert? Reach out today for a consult.

Plastic Resources, Inc. info@plastic-resources.com 614-471-9478 www.platsic-resources.com